Glass Steps Into the Temporary Bonding Spotlight

...

Dr. Terry Brewer’s discovery of anti-reflective coatings resulted in a revolution in the global microelectronics industry and ushered in today’s high-speed, lightweight electronic devices.

Learn MoreAdvanced materials for the protection and enhancement of optics, displays, and other microelectronics.

Learn MoreOur line of products stretches across the whole spectrum of lithography wavelengths and is the most comprehensive product lineup in the industry.

Learn MoreAt Brewer Science, we are focused on delivering critical, real-time information to our customers to help them achieve their goals, solve their problems, and improve their current systems.

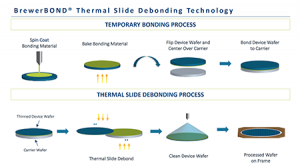

Learn MoreBrewer Science is revolutionizing packaging solutions with innovative bonding and debonding technologies.

Learn More

| Wax | BrewerBOND® 230 Material | |

|---|---|---|

| Thickness Range | ~ 10 – 35 µm | 20 µm – 150 µm |

| Coating Throughput | Requires multiple coats | Single-coat process |

| Bonding Temperature Range | 95ºC - 110ºC | 100ºC – 130ºC |

| Debonding Temperature Range | 95ºC - 110ºC | 150ºC – 200ºC |

| Thermal Stability Temperature Range | < 120ºC | ≤ 250ºC |

For coatings thicker than 20 µm, BrewerBOND® 220 material is a good option as an alternative solution to typical wax adhesives. It offers significant advantages because it can be applied with a one-coat process. The material provides up to a 160-μm film with a single coat and customized spin process. BrewerBOND® 220 material enables backside temperature processing up to 250°C with minimal device wafer bowing. BrewerBOND® 220 material does not introduce additional stress in the bonded stack. This versatile material can be used for the thermal slide or mechanical debonding methods.