Introduction to Wet Etching of Silicon

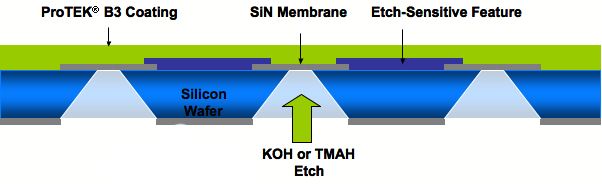

- Wet etching uses KOH, TMAH, or other alkaline etchants

- Wet etching results in an anisotropic etch along the silicon crystal plane

- An etch protective mask is required during wet silicon etching

- Oriented wafers are commonly used

Wet etching processes are used to fabricate many commercial devices:

- Pressure Sensors

- MEMS Microphones

- MEMS Accelerometers

- High-Brightness LEDs

- Microfluidic Devices

- Advanced IC Packaging

All Brewer Science® protective coatings allow micromachining to take place closer to packaging, which simplifies the processes and improves device yield. The low-temperature processing of these films allows them to be coated over CMOS structures, unlike SiO2 or SiN layers.

Protective coatings also allow the release of membranes and proof masks and the creation of through-silicon vias (TSVs) as a last step before packaging. This capability improves the process and device yield.