Participating in the Next-Generation Semiconductor Packaging Consortium “JOINT3”

Brewer Science has joined the next-generation semiconductor packaging consortium “JOINT3.”

September 3, 2025 – JOINT3 is a co-creation evaluation platform established by Resonac Corporation (President and CEO: Hidehito Takahashi, hereinafter “Resonac”) with the aim of accelerating the development of materials, equipment, and design tools optimized for panel-level organic interposers through collaboration among material, equipment, and design companies.

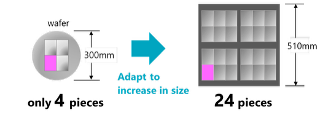

JOINT3 brings together global leaders in semiconductor materials, equipment, and design. Using a prototype line for 515 x 510-mm panel-level organic interposers, the consortium promotes the development of materials, equipment, and design tools optimized for panel-level organic interposers.

“At Brewer Science, our participation in the JOINT3 Consortium reflects our continued commitment to driving innovation in the semiconductor industry,” states Dr. Srikanth (Sri) Kommu, co-CEO at Brewer Science. “Leveraging our advanced materials expertise—particularly in high-performance polymer solutions—we collaborate with industry leaders to pioneer technologies that enable smarter, more sustainable solutions. Through this consortium, we aim to accelerate the development of next-generation semiconductor packaging, supporting a connected, intelligent, and environmentally responsible future.”

In recent years, packaging technologies in the back-end process have become one of the key technologies for next-generation semiconductors, which are essential for rapidly expanding markets such as generative AI and autonomous driving. Among these technologies, 2.xD packages, which involve arranging multiple semiconductor chips in parallel and connecting them via an interposer, are expected to see further growth in demand due to the increasing data communication capacity and speed requirements. As semiconductor performance improves, interposers are becoming larger in size, and there is a shift from silicon interposers to organic interposers made from organic materials. Regarding manufacturing methods, the conventional approach involves cutting rectangular pieces from circular wafers. However, as interposers increase in size, the number of interposers that can be obtained from a single wafer decreases, posing a significant challenge. To address this issue, a manufacturing process that transitions from circular wafer shapes to square panel shapes is gaining attention, as it allows for an increased number of interposers to be

produced.

About Resonac

Resonac is a functional chemical company established as a result of the integration of Showa Denko and former Hitachi Chemical in January 2023. The Company’s sales revenue of semiconductor and electronic materials business for 2024 was about 450 billion yen. The Company is a world-class leader particularly in semiconductor materials for packaging process. The integration of the two companies has enabled Resonac to design functions of materials as well as to develop them in-house, going all the way back to raw materials. The trade name “RESONAC” was created as a combination of two English words, namely, the word of “RESONATE” and “C” as the first letter of CHEMISTRY. The Company will make the most of its co-creative platform, and accelerate technological innovation with semiconductor manufacturers, material manufacturers, and equipment manufacturers inside and outside Japan.

For detail, please refer to our Website.

Resonac Holdings Corporation: https://www.resonac.com/

For further information, contact:

Resonac Holdings Corporation

Media Relations Group, Brand Communication Department

Phone: +81-3-6263-8002

About Brewer Science

Brewer Science is a global leader in developing and manufacturing next-generation materials and processes that foster the technology needed for tomorrow. Since 1981, we’ve expanded our technology portfolio within advanced lithography, advanced packaging, smart devices, and printed electronics to enable cutting-edge microdevices and unique quality monitoring systems for water and air applications. We are Certified Employee-Owned and a Certified B Corporation™, using our business as a force for good. Our headquarters are in Rolla, Missouri, with customer support throughout the world. Learn more at: www.brewerscience.com.

Brewer Science Company Contact:

Nathan Ayres

Tel: (US) +1.573.364.0444, ext. 1923

Email: nayres@brewerscience.com