Benefits of Brewer Science® EUV Materials

- Less line width roughness (LWR) and line edge roughness (LER)

- Less pattern collapse and micro-bridging caused by high aspect ratios of printed features

- Better adhesion

- Less effects from strong capillary forces during development

- Less outgassing than positive-tone photoresists during EUV exposure

Product-Specific Properties

| Material | Thickness | Spin Speed (rpm) | Bake | Viscosity (cP) |

|---|---|---|---|---|

| E²Stack® AL412-301.5 | 12 nm | 1500 rpm | 205°C, 60 s | 1.57 |

| E²Stack® AL412-302 | 20 nm | 1500 rpm | 205°C, 60 s | 1.57 |

| E²Stack® AL412-306 | 60 nm | 1500rpm | 205°C, 60 s | 1.75 |

Brewer Science began working on EUV materials 15 years ago with a focus on materials to enhance the process window of existing EUV resists. In that time, Brewer Science has created multiple assist layer materials under the E2Stack® material umbrella. These materials are the industry standard for EUV underlayers, and enable faster development of EUV photoresist and processes. Over the years, these EUV materials have expanded into multilayer materials as well as novel metal-containing assist layers to improve pattern transfer and EUV dose sensitivity. Brewer Science continues to work closely with all major industry EUV players to ensure the smooth transition from R&D to production.

Why EUV materials

The biggest problem facing lithographers using EUV is the RLS trade-off: simultaneous improvement of resolution, line width roughness, and photosensitivity.

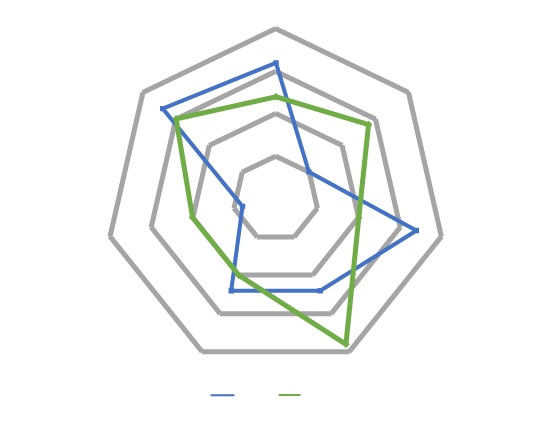

This graphic from ITRS 2015 shows the comparison of DSA and EUV.

Related Products

OptiStack® multilayer systems are our flagship lithography technology, and are used for leading-edge high volume IC manufacturing.

ARC® antireflective coatings are the industry benchmark for reflection control and light absorption during photolithography.