In recent years, sustainable manufacturing has become increasingly vital in the materials industry with growing concerns about the impact of manufacturing on the environment. Minimizing the intrinsic risks associated with any manufacturing operation while maximizing the quality and opportunities that arise with improved products is and should be the goal of almost every manufacturer today. At Brewer Science, we lead by example by being a manufacturer committed to sustainability in producing state-of-the-art materials.

According to the US Department of Commerce’s Sustainable Manufacturing Initiative (SMI), sustainable manufacturing is a description given to all “manufacturing processes that minimize negative environmental impacts, conserve energy and natural resources, are safe for employees, communities and consumers and are economically sound.” In other words, it is an all-encompassing term that includes different aspects that lie under the three pillars of sustainability—environment, economy, and society. Table 1 shows a list of those aspects.

Table 1. The three pillars of sustainable manufacturing. (OECD)

|

Sustainable Manufacturing |

||

|

Environment |

Economy |

Society |

|

Minimal production of waste and emissions |

Job creation |

Good working conditions |

|

Efficient use of energy and resources |

Investment in infrastructure |

Good community relations |

|

Protection of biodiversity |

Contribution to local economies |

Respecting human rights |

|

Use of environmentally sound materials and energy |

Driving innovation |

Ensuring product safety |

|

Minimal use of hazardous substances |

Sales and profit generation |

Complying with the law |

What makes companies pursue sustainability?

More and more manufacturers are recognizing and achieving advantages, both financially and environmentally, by applying sustainable practices. Some of the reasons that have incentivized companies to adopt sustainability include increasing operational efficiency by minimizing costs and waste, maintaining and reinforcing public trust in their brand, building longstanding success and sustainability of their business, and responding to constraints and opportunities brought about by regulations. It is important to note that not only does sustainable manufacturing help produce sustainable products, but it also helps render the fabrication processes more sustainable, leading to improved total benefits for the company.

For 40 years, Brewer Science has shown its dedication to ensuring sustainability in its manufacturing processes time and time again. Such a commitment has elevated the company to become an example of sustainable manufacturing, such as achieving Certified B Corporation™ certification through its sustainable manufacturing processes. As an international producer of materials and processes that enable innovative microdevices and monitoring systems, we have achieved and maintained proper environmental sustainability, producing high-quality products by achieving zero-defect manufacturing, and sending no waste to landfills—a feat that has earned GreenCircle® Zero Waste to Landfill certification since 2016.

Brewer Science’s journey to environmental sustainability

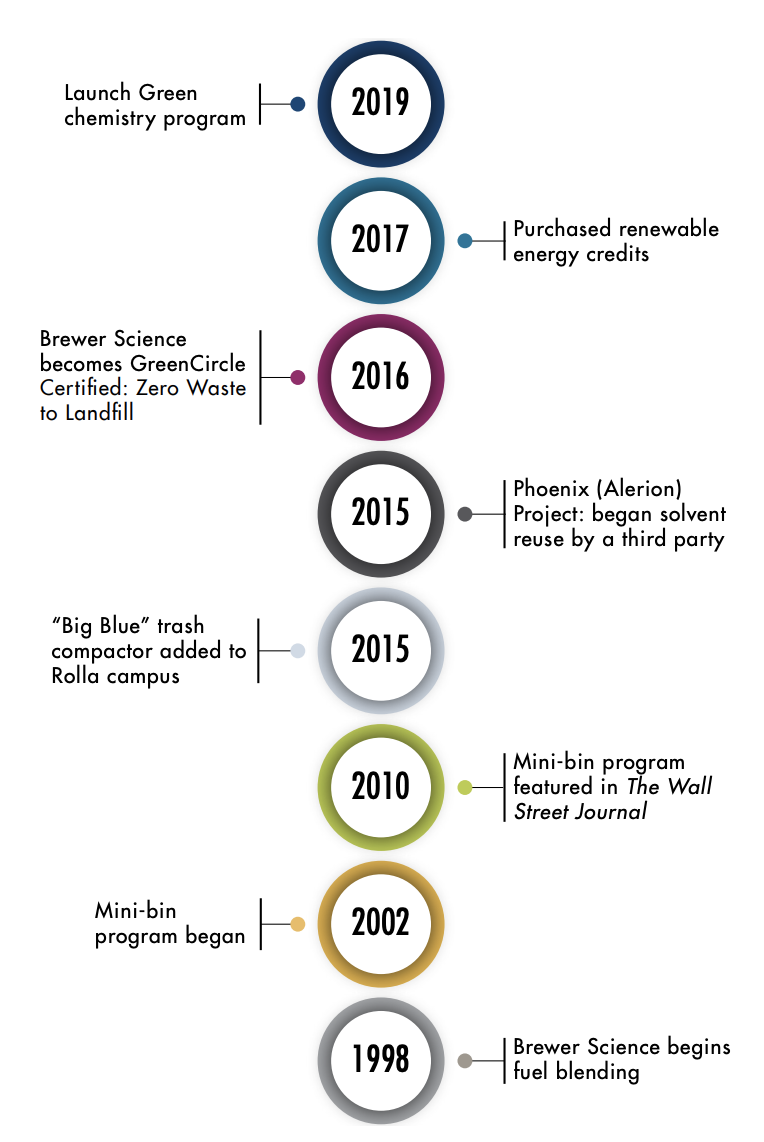

Since its first fuel-blending program in 1998, Brewer Science has taken many steps to sustain its commitment to responsible waste management and environmental sustainability.

In 2019 alone, Brewer Science was able to divert 314 tons of waste from landfill by using various methods, including waste treatment, waste-to-energy, material reuse, recycling, metal recovery, and fuel blending. All these different techniques are effective for different types of wastes, which have enabled Brewer Science to reach zero-waste-to-landfill and maintain that position for six consecutive years. In addition, the company has displayed effective resource conservation as over 60% of its electricity usage in 2019 has come from wind energy. And it does not stop there. Brewer Science’s carbon emissions have been decreasing year after year thanks to their Green Program efforts.

This is an example of the direction that the materials industry is heading as we embark on a decade of environmental and economic challenges that make such commitments all the more important.

Materials and Products of Brewer Science

Being a hub for innovative manufacturing, Brewer Science has made certain that its products and technologies not only are state-of-the-art and defect-free but also enable highly reliable fabrication of microdevices that can be used in applications such as smartphones, tablet computers, televisions, digital cameras, and LED lighting. Furthermore, its commitment to delivering materials with zero defects has only been reinforced with improved materials research and technology into advanced manufacturing areas like lithography, printed electronics, high-temperature adhesives, and advanced packaging. Such work has led to the development of next-generation microdevices and unique monitoring systems in industrial and environmental applications.

From protective coatings to anti-reflective coatings all the way to high-temperature adhesives and bonding technologies for wafer-level packaging, Brewer Science has developed advanced materials leading to effective fabrication processes. You can learn more about Brewer Science’s sustainability initiatives on the Going Green page, or talk to an expert today to learn how Brewer Science’s products can benefit your business.