Brewer Science’s High-Temperature-Stable, Gapfilling Planarizing Material Revolutionizes Advanced ArF and EUV Processes

OptiStack® SOC450 material provides zero shrinkage up to 550°C when baking in N2

June 15, 2023 – Rolla, MO – Brewer Science, Inc., a global leader in developing and manufacturing next-generation materials for the microelectronics and optoelectronics industries, is thrilled to announce the latest breakthrough in high-temperature gapfilling materials – OptiStack® SOC450 material, enabling advanced node processes by providing unparalleled performance at extreme temperatures.

A basic overview of a spin-on carbon and the need for a high-temperature stable material.

Overcoming the Industry Compromise: Thermal Stability for Planarization and Gapfilling

One of the greatest challenges in the advanced ArF and EUV industries has been finding a material that can withstand high temperatures without sacrificing its planarization and gapfilling capabilities.

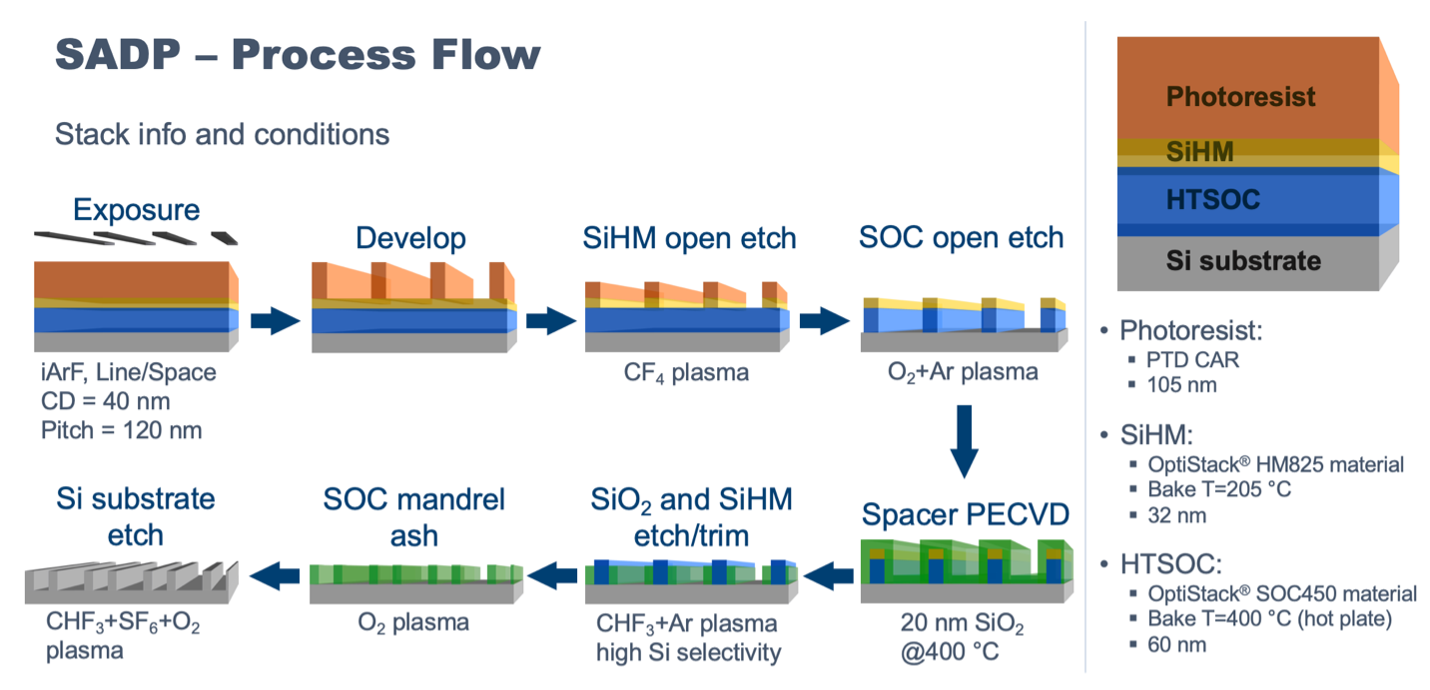

Shrinkage in spin-on glass (SOG) coatings, or annealing processes, can result in incomplete coverage, pattern distortion, delamination, or cracking. Insufficient thermal stability properties can affect subsequent process steps, compromising the overall performance and reliability of the device. To prevent significant yield loss caused by unstable materials during high-temperature annealing, such as those necessary in self-aligned double patterning (SADP) applications, it’s important to ensure gapfilling materials are stable over 400°C.

A typical low-temperature SOC has 50% weight loss when baked to 400°C which makes planarization suffer due to the film shrink.

OptiStack® SOC450 Material Enables SADP Processing with High Thermal Stability

With OptiStack® SOC450 material EUV processes will no longer have to sacrifice temperature stability for superior gapfilling and planarization.

OptiStack® SOC450 material is a carbon-based high-aspect-ratio spin-on-carbon material designed to withstand high temperatures and provide low shrinkage, offering significant benefits to ArF, EUV, SADP, SAQP, 3D NAND, and advanced memory processes.

The following simplified example illustrates one potential application of OptiStack® SOC450 material to improve a SADP process by utilizing high-temperature CVD deposition of the spacer.

Key Features and Benefits of OptiStack® SOC450 Material

Zero Shrinkage: Unlike traditional SOC materials, OptiStack® SOC450 material boasts a remarkable 0% shrinkage when subjected to high-temperature baking, up to 550°C when baking in N2 after a 170°C soft bake step. This means precise planarization and gapfilling are possible without worrying about dimensional changes, maintaining the integrity of valuable components.

High Thermal Stability: OptiStack® SOC450 material can withstand high-temperature vacuum-deposited SiXn films over 200 nm. The high thermal stability enables integration schemes utilizing chemical vapor deposition (CVD) and/or atomic layer deposition (ALD) processes.

OptiStack® SOC450 material offers narrow trench and high-aspect ratio gapfilling, including a complete fill, without void or delamination.

CMP Compatibility: When a strict global-level planarization is needed, OptiStack® SOC450 material can be further planarized by chemical mechanical planarization (CMP) for use in high topography, and/or highly variable pattern density devices. With many spin-on carbons facing challenges with long-range planarization, the ability to OptiStack® SOC450 material enables superior planarization by controlling the rate of removal, based on the slurry and pad type.

CVD Processing: Chemical vapor deposition (CVD) can pose many problems if the spin-on carbon material vaporizes or sublimates, including contamination that leads to defects. Ineffective CVD can cause film thickness variation or that challenge the integrity of the device. Off-gassing, delamination, and cracking are also seen with traditional SOC thermal decompositions. OptiStack® SOC450 material does not sublimate or vaporize in conditions up to 400°C, and demonstrates superior stability in conditions up to 550°C.

Increase Efficiency: High carbon content of OptiStack® SOC450 material enables CF4 plasma etch rates better than SiOx. Ultralow metal ions less than 1,000 part-per-trillion ensure decreased post-etch defects. Additionally, the solubility in fab-friendly solvents and compatibility with other spin-on materials eliminates potential drain clogging issues.

OptiStack® SOC450 material will redefine what you expect from high-temperature-stable, gapfilling planarizing materials. Its unique combination of thermal stability, zero shrinkage, and exceptional performance will enable new possibilities for your products, helping you achieve unprecedented levels of quality and reliability. Don’t settle for compromises between thermal stability and superior gapfilling when you can have it all with OptiStack® SOC450 material. Connect with a product expert or learn more by visiting our website.

About Brewer Science

Brewer Science is a global leader in developing and manufacturing next-generation materials and processes that foster the technology needed for tomorrow. Since 1981, we’ve expanded our technology portfolio within advanced lithography, advanced packaging, smart devices, and printed electronics to enable cutting-edge microdevices and unique monitoring systems for industrial, environmental, and air applications. Our relationship-focused approach provides outcomes that facilitate and deliver critical information. Our headquarters are in Rolla, Missouri, with customer support throughout the world. We invite you to learn more about Brewer Science at www.brewerscience.com.

###

Company Contact:

Nathan Ayres

Tel: (US) +1.573.364.0300, ext. 1923

Email: nayres@brewerscience.com